LIGHT GAUGE STEEL

There are numerous advantages to light gauge steel (LGS). Compared to traditional construction materials, these are the most important benefits:

1. The material is more sustainable.

2. It has a greater strength to weight ratio.

3. It is more accurate.

4. It has greater consistency.

As the world’s focus shifts towards sustainability, so does the construction industry. Traditional construction materials are now beginning to show their age and are rapidly declining in popularity in favour of more sustainable alternatives. As renewable resources such as timber become less desirable, it is increasingly obvious light gauge steel construction is the most sustainable solution for our future.

With a greater strength to mass ratio than traditional materials, not only is light gauge steel more durable and ductile, it is also more consistent in composition to the likes of timber & brick.

Sustainability & Strength

Accuracy & Consistency

The accuracy of light gauge steel comes from its non-porous composition. As a result, it is accurate to less than a quarter of a mm when formed, impenetrable to insects, and impervious to environmental factors that may cause it to shrink and swell like timber or corrode in coastal/desert regions.

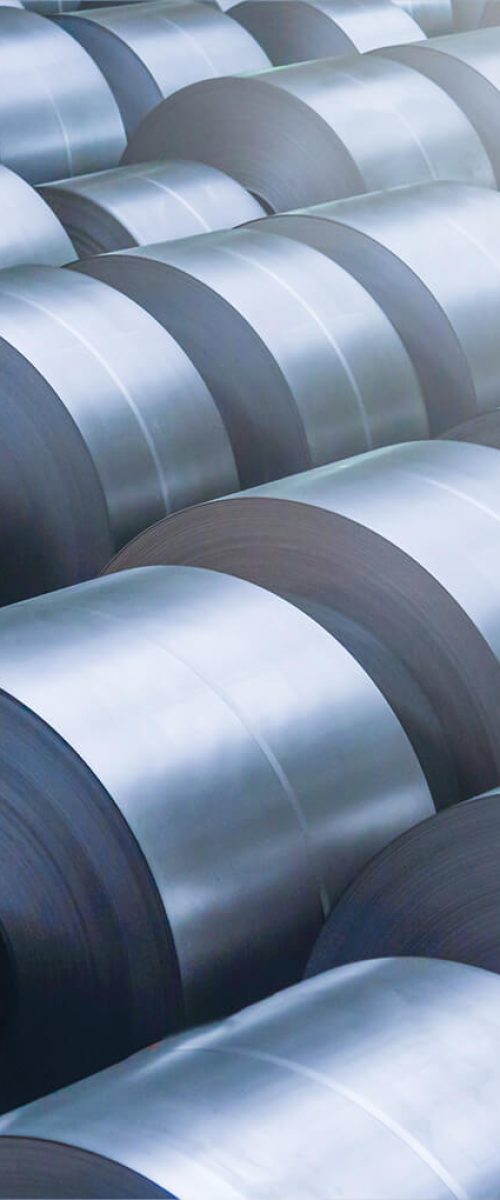

The consistency of light gauge steel results from the cold forming process itself where iron ore and carbon are fused in the controlled environment of a furnace, then poured into slabs before being reduced into thinner strips called ‘hot band.’ It is this controlled process that ensures a consistent product, something almost impossible with natural products like timber.

Keyword: light gauge steel LGS

Titel: LIGHT GAUGE STEEL (LGS)

There are numerous advantages to light gauge steel (LGS). Compared to traditional construction materials, these are the most important benefits:

– the material is more sustainable

– it has a greater strength to weight ratio

– it is more accurate

– it has greater consistency

Sustainability

As the world’s focus shifts towards sustainability, so does the construction industry. Traditional construction materials are now beginning to show their age and are rapidly declining in popularity in favour of more sustainable alternatives. As renewable resources such as timber become less desirable, it is increasingly obvious light gauge steel construction is the most sustainable solution for our future.

Strength

With a greater strength to mass ratio than traditional materials, not only is light gauge steel more durable and ductile, it is also more consistent in composition to the likes of timber & brick.

Accuracy

The accuracy of light gauge steel comes from its non-porous composition. As a result, it is accurate to less than a quarter of a mm when formed, impenetrable to insects, and impervious to environmental factors that may cause it to shrink and swell like timber or corrode in coastal/desert regions.

Consistency

The consistency of light gauge steel results from the cold forming process itself where iron ore and carbon are fused in the controlled environment of a furnace, then poured into slabs before being reduced into thinner strips called ‘hot band.’ It is this controlled process that ensures a consistent product, something almost impossible with natural products like timber.